RECOMMEND SOLUTIONS

RELATED PRODUCTS

Case Study| Southeast Asia Substation Remote Control Upgrade: Four-Faith Reinforces Grid Security

Date:2025-12-31 15:38:32

Amidst the global wave of energy digital transformation, remote monitoring and intelligent control of power systems have become core components in building smart grids. Achieving precise remote management and control of substation equipment through IoT technology not only enhances power operation and maintenance (O&M) efficiency but also reinforces the security and stable operation of the grid. This is both a critical path for the power industry to address O&M challenges and an inevitable choice for driving energy networks towards intelligence and high efficiency.

Leveraging its industrial-grade communication devices and standardized protocol integration capabilities, Four-Faith developed a secure and reliable remote control solution for a national power company in Southeast Asia. Through technological innovation, Four-Faith propelled the evolution of the power system towards automation, digitalization, and low-carbon operation, providing a practical blueprint for global smart grid construction.

Project Background

A regional substation in Southeast Asia required remote switching control of 20kV relays to enhance grid dispatch flexibility and response speed.

The company had already established a control platform based on a Siemens SCADA system. To avoid the costs and time losses associated with system replacement, they specified a key requirement: achieving direct remote control of on-site relays via the standard DNP3 protocol without replacing the existing SCADA master station. Furthermore, the solution needed to utilize a 4G Private APN (Access Point Name) network to ensure data transmission confidentiality and security.

Project Solution

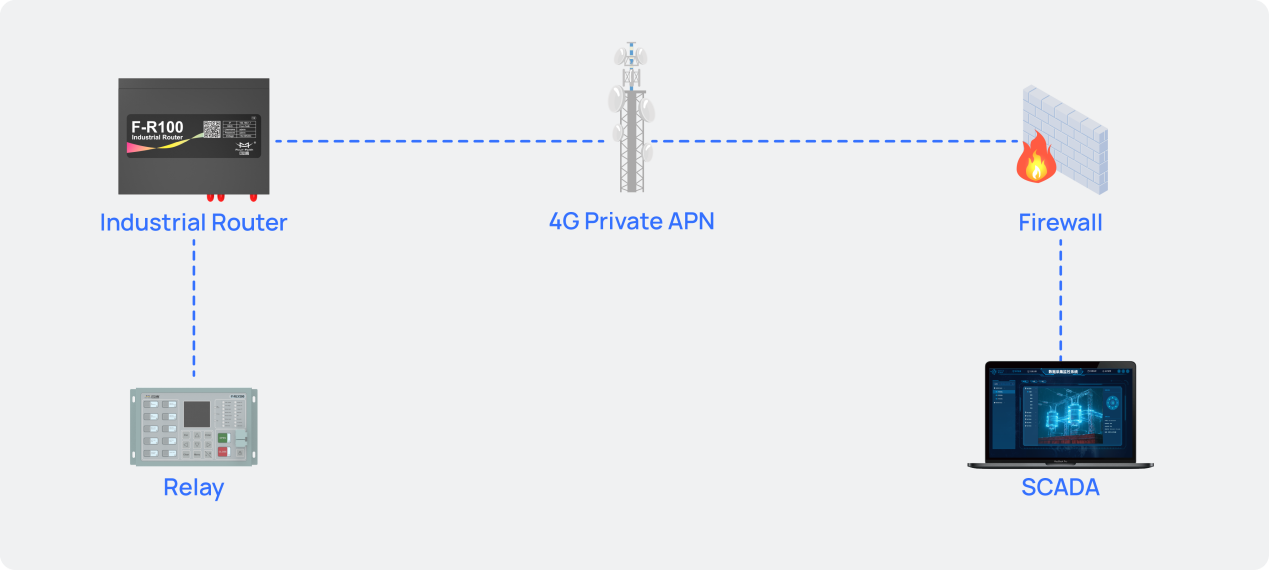

To meet the customer's core requirements for seamless DNP3 protocol integration, secure transmission over a 4G Private APN, and industrial-grade device reliability, Four-Faith provided a communication solution centered on the F-R100 V2 Industrial 4G Router, enabling efficient implementation of remote control.

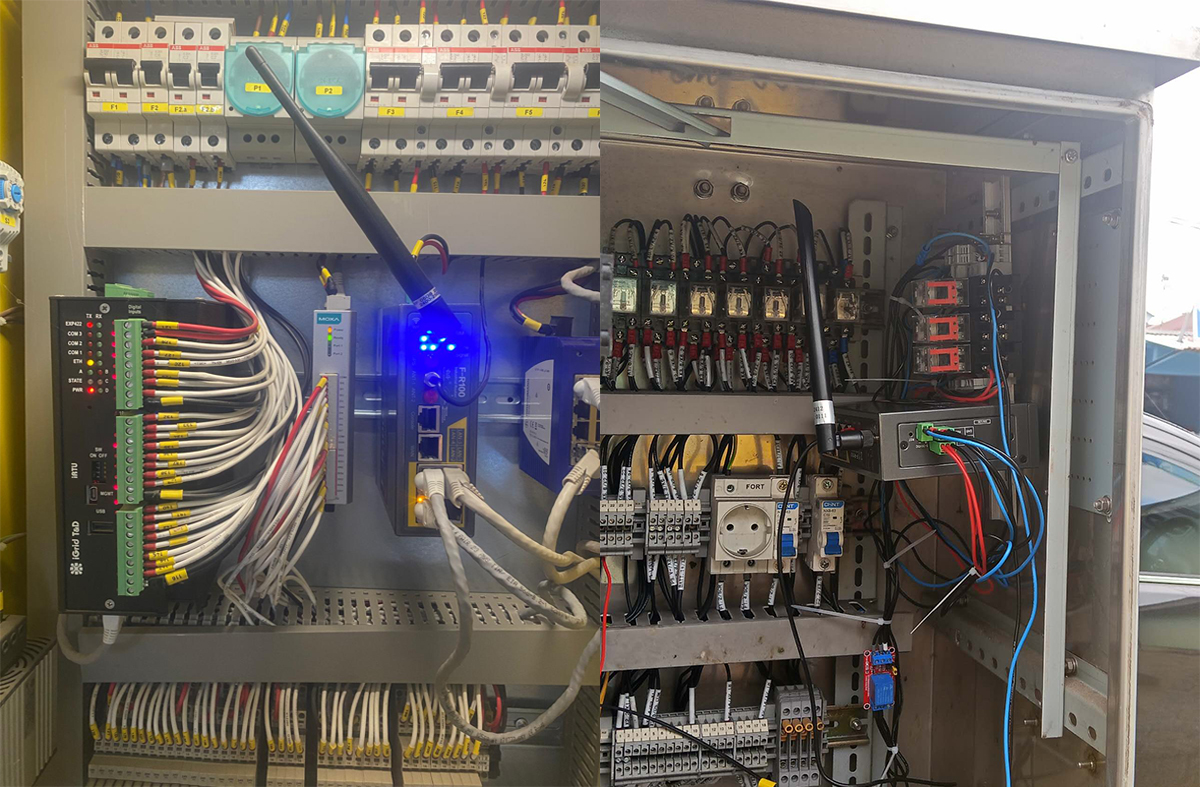

Acting as the communication bridge between the field site and the SCADA master station, the F-R100 V2 features dual DI (Digital Input), single DO (Digital Output), and relay interfaces, supporting digital input/output and local linkage control. It is compatible with the standard DNP3 Outstation (Slave) mode, perfectly adapting to the customer's existing Siemens SCADA system. The router can directly respond to Class 0-3 polling requests and Direct Operate control commands.

Network access is achieved via the customer's dedicated 4G Private APN SIM card, with a fixed IP address assigned to ensure a stable connection between the SCADA master and field devices. Flexible configuration of DNP3 addresses, DO point numbers, and other parameters is possible through a web interface, simplifying the debugging process. Its industrial-grade design enables it to withstand the harsh substation environment characterized by high temperatures, high humidity, and electromagnetic interference (EMI), guaranteeing stable 24/7 operation.

Implementation Path

- Device Commissioning: The technical team collaborated with the customer to complete DNP3 address mapping and communication protocol testing, ensuring stable router-to-SCADA master connectivity.

- Functional Verification: Remote switch control of on-site relays by the SCADA system via TCP connection was successfully implemented, with stable command response and latency consistently below 200ms.

- Delivery & Training: Localized configuration guides and remote support were provided, empowering the customer's team to independently perform subsequent O&M tasks.

Innovative Technology Highlights

- Seamless Compatibility: No modification required to the existing SCADA system, enabling rapid deployment and reducing technical barriers and upgrade costs.

- Industrial-Grade Reliability: The Four-Faith F-R100 V2 industrial router is specifically designed for power scenarios, offering resistance to EMI and adaptability to high-temperature/high-humidity environments.

- Dual Security Safeguards: The Private APN + Fixed IP architecture ensures secure and controllable data transmission.

- Flexible Scalability: Supports custom configuration via a web page and compatibility with multiple industrial protocols (e.g., IEC 104, MQTT), providing ample space for future upgrades.

Project Outcomes

- Enhanced Remote Control Efficiency: Direct issuance of switch commands via the SCADA system significantly reduced the frequency of manual patrol inspections and on-site operations, transforming the traditional manpower-dependent O&M model.

- Improved Emergency Response: During critical events, the SCADA system can rapidly issue commands to achieve swift fault isolation, ensuring grid stability.

- Effective Reduction in Total Cost of Ownership (TCO): The wireless communication approach eliminated extensive cabling costs, while the industrial-grade, maintenance-free device reduced long-term O&M expenditures, achieving lifecycle cost reduction and efficiency gains.

- Ample System Expansion Potential: The device's compatibility with multiple industrial protocols enables seamless integration of future I/O devices and control requirements, reserving a technical interface for smart grid evolution.

Industry Demonstration Significance

An executive from the power company commented: *"Four-Faith's communication solution perfectly resolved the dual challenges of protocol compatibility and network security. The industrial-grade stability of the F-R100 V2 exceeded expectations!"* The project has been included in the company's standardized smart grid promotion list. Future plans involve deployment across more regions and exploration of integration with IoT platforms to achieve centralized O&M for multiple substations.

Four-Faith Intelligent Manufacturing: Empowering the New Era of Industrial Interconnection

As a leader in industrial communication solutions, Four-Faith consistently anchors its approach in technology, deeply penetrating core sectors like power, manufacturing, and energy. The success of the F-R100 V2 in this project validates the high compatibility and stability of domestically produced industrial equipment in complex scenarios, showcasing Four-Faith's full-stack service capabilities encompassing "Protocols + Hardware + Application Scenarios".

Looking ahead, we will continue to deepen our technological capabilities in industrial protocol parsing, edge control, and secure transmission. We will collaborate with global partners to build an intelligent, reliable, and green industrial interconnection ecosystem, injecting core momentum into the development of new quality productive forces within the energy industry

TAGS: Substation Remote Control Upgrade [Previous Page]

Previous Page:Four Faith Industrial Gateways Deployed in Norwegian Charging Network

next page:last_page